The aerospace and automotive industries are on the precipice of a new era, driven by the development and innovative use of modern materials. Traditional materials like steel and aluminum remain central to these industries, but advancements in composites, alloys, and smart materials are opening new doors for performance, safety, and efficiency.

This blog explores the growing role of modern materials in aerospace and automotive applications, focusing on how innovation is redefining structural integrity, fuel efficiency, and sustainable practices. If you’re an aerospace engineer, automotive enthusiast, or material scientist, this deep-dive is for you.

The Evolution of Modern Materials

Engineering breakthroughs in recent decades have accelerated the availability and functionality of advanced materials. Modern materials include composites, high-performance alloys, ceramics, and smart materials with properties that outperform traditional counterparts.

For instance, composites offer strength-to-weight advantages, while advanced alloys provide enhanced heat resistance and mechanical durability. Smart materials—those that change properties in response to environmental inputs like temperature or pressure—are increasingly valuable in creating adaptive and cutting-edge designs.

Together, these materials are rewriting what engineers, designers, and manufacturers thought possible in both aerospace and automotive engineering.

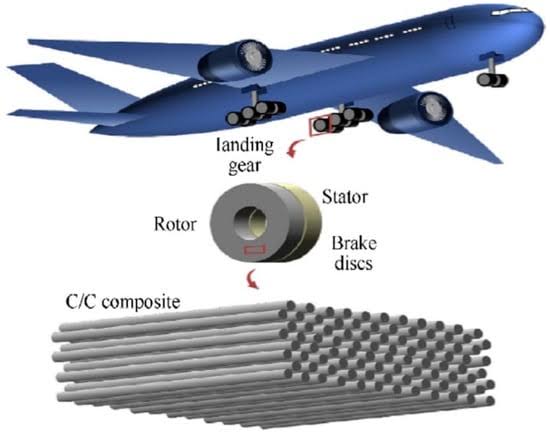

The Role of Composites in Aerospace Applications

The aerospace industry has always demanded materials that combine lightweight properties with strength and resilience. This need has led to a surge in the adoption of composite materials, such as carbon fiber-reinforced polymers (CFRPs). Today’s aircraft like Boeing’s 787 Dreamliner and Airbus A350 utilize composites extensively, accounting for up to 50% of their structure.

Key Benefits in Aerospace:

- Weight Reduction

Weight is critical in aerospace for maximizing fuel efficiency and reducing emissions. Composites deliver the strength of metals like aluminum while being significantly lighter.

- Fatigue and Corrosion Resistance

Unlike traditional metals, composites resist fatigue and corrosion, ensuring longer service life and reduced maintenance costs.

- Design Flexibility

With composites, engineers can explore complex geometries and streamlined designs, free from the limitations of metallic materials.

Smart materials also begin to play a role in aerospace. For instance, morphing wings made with shape-memory alloys can enhance the aerodynamic efficiency of aircraft by responding to real-time aerodynamic needs.

To learn more about composite solutions, check out this trusted composite material manufacturer.

Modern Materials Driving Automotive Innovation

The automotive industry is no stranger to the challenge of balancing performance, safety, and cost-efficiency. Modern materials are proving to be essential in meeting these stringent requirements—especially for sustainable and electric vehicle (EV) designs.

Composites and Lightweighting

Reducing vehicle weight has become a central focus, especially to improve efficiency and increase battery range in EVs. High-strength composites such as glass fiber and carbon fiber are replacing elements in car frames and interiors, significantly reducing overall weight without sacrificing strength.

For example, BMW pioneered this approach in their i-Series EVs, which utilize carbon fiber-reinforced polymers throughout the body. This strategy reduces weight and improves handling and durability.

Advanced Alloys for High-Performance Engines

High-performing alloys such as titanium aluminides and magnesium alloys are pushing engine performance to new heights. These materials are excellent at withstanding high-temperature environments, making them ideal for supercars and racing applications.

Smart Materials in Automotive Features

Modern automobiles are integrating smart materials for more functional and adaptable designs. Shape-memory alloys and polymers are used in everything from adaptive suspension systems to retractable spoilers. Vehicles that use self-healing paint coatings are benefiting from a new generation of materials that can repair minor scuffs and scratches, extending the life of the car’s exterior.

Sustainability Through Material Innovation

Both industries are increasingly focused on sustainability—reducing carbon footprints while meeting high-performance benchmarks. Modern materials are at the heart of these efforts.

Recycling and Life-Cycle Management

Many modern materials are designed with recycling in mind. For example, some automotive manufacturers are exploring thermoplastic composites that can be melted down and reused with minimal material degradation.

Renewable and Bio-Based Materials

Materials innovation is also leaning into bio-based solutions. For instance, plant-based resins are being incorporated into composites, diminishing the reliance on synthetic, petroleum-based products. Similarly, bio-fibers like flax and hemp are used as reinforcements in composite structures.

Challenges in Material Adoption

While the benefits of modern materials are substantial, there are challenges to their adoption, including:

- High Cost: Advanced composites and alloys can be expensive to produce at scale.

- Manufacturing Constraints: Some materials are challenging to process or require specialized equipment.

- Regulatory Concerns: Emerging materials must meet rigorous safety and environmental standards before adoption.

Overcoming these challenges requires collaboration between material scientists, engineers, and manufacturers to create economically feasible and scalable solutions.

A Future Built with Modern Materials

Looking ahead, the innovations in modern materials are set to transform aerospace and automotive industries even further. Current research into multifunctional materials—such as composites that integrate energy storage—point toward new possibilities for design and functionality. Additionally, 3D printing with advanced materials could revolutionize prototyping and manufacturing processes.

For consumers, this means vehicles and aircraft that are safer, more efficient, and environmentally friendly. For professionals in the industry, the opportunities for innovation are limitless.