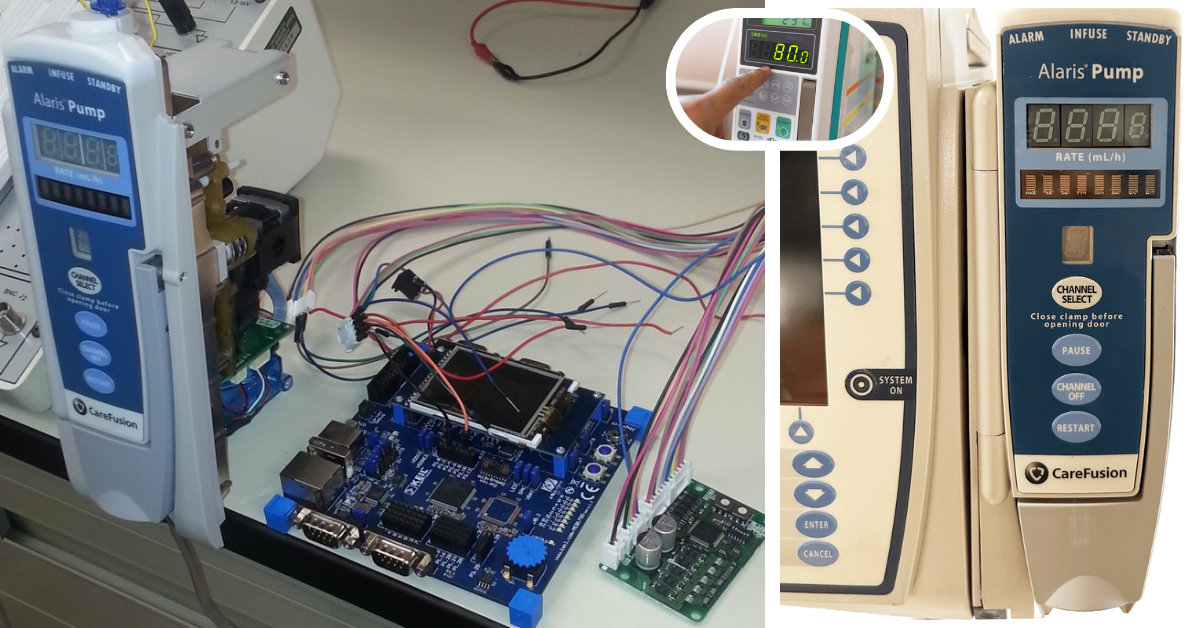

Introduction to the Alaris 8100 L medical equipment

The Alaris 8100 L is a key player in the world of medical equipment, trusted by healthcare professionals for its reliability and precision. However, even the most dependable machines can experience wear and tear over time. One common problem that can arise is cracking—an issue that poses risks to both device functionality and patient safety. In this post, we’ll explore the intricacies of maintaining your Alaris 8100 L while providing insights into recognizing cracks early on. If you’ve ever come across a picture of cracked Alaris 8100 L equipment, you’ll want to read on to understand how it impacts care delivery and what you can do about it.

Common issues and causes for the Alaris 8100 L to crack

The Alaris 8100 L is a trusted piece of medical equipment, but it’s not without its vulnerabilities. One common issue that leads to cracking is environmental stress. These devices often face fluctuations in temperature and humidity which can weaken the material over time.

Physical impact also plays a significant role. Being moved frequently or placed under heavy items can cause undue pressure on the device’s casing. Even minor drops can create cracks that worsen if not addressed promptly.

Additionally, improper cleaning techniques may contribute to damage as well. Using harsh chemicals or abrasive materials can erode protective coatings, making the plastic more susceptible to fractures.

Aging components are a natural part of any machine’s lifecycle. As parts wear down, they lose their structural integrity and become prone to cracking with everyday use. Recognizing these factors early on can help mitigate further issues down the line.

The importance of regular maintenance and repairs for medical equipment

Regular maintenance of medical equipment is crucial for ensuring safety and reliability. Equipment like the Alaris 8100 L plays a vital role in patient care, so its functionality cannot be compromised.

Routine checks help identify issues before they become severe problems. This proactive approach minimizes downtime and ensures that devices are ready when needed most.

Repairs should not be viewed as mere inconveniences but rather as necessary investments. Quality repair services can extend the lifespan of your equipment significantly.

Neglecting regular upkeep may lead to unexpected failures, which can jeopardize patient outcomes. Keeping equipment in optimal condition fosters trust between healthcare providers and patients.

Investing time in maintenance translates into better performance, enhanced accuracy, and ultimately improved patient safety. It’s a fundamental aspect of responsible healthcare management that shouldn’t be overlooked.

Tips for preventing cracks in the Alaris 8100 L

To prevent cracks in the Alaris 8100 L, start by ensuring proper storage. Avoid placing heavy items on top of the device and keep it in a designated area where it won’t be bumped or jostled.

Regular cleaning is essential. Use soft cloths to wipe down surfaces, avoiding harsh chemicals that could damage materials.

Train staff thoroughly on handling techniques. Educating users about gentle handling can significantly reduce incidents of accidental damage.

Consider implementing a routine inspection schedule. Regular checks can identify wear and tear before they lead to more significant issues like cracking.

Invest in protective cases when transporting the equipment between locations. This extra layer of safety can make all the difference during movement or transit.

Cost-effective options for repairing a cracked Alaris 8100 L

Repairing a cracked Alaris 8100 L doesn’t have to break the bank. There are several cost-effective solutions available that can restore functionality without draining your budget.

One option is to reach out to specialized medical equipment repair companies. Many offer competitive rates and can provide repairs quickly, ensuring minimal downtime for your equipment.

Another approach is exploring certified refurbished parts. These components often come at a fraction of the cost of new ones but maintain high quality and reliability standards.

Consider preventive measures as well. Regular maintenance checks can catch minor issues before they escalate into costly repairs, saving you money in the long run.

Engaging with your manufacturer or vendor might reveal warranty options or service plans tailored for such damages, offering additional savings while keeping your equipment in top shape.

The impact of a cracked Alaris 8100 L on patient care and safety

A cracked Alaris 8100 L can significantly compromise patient care. The integrity of this essential medical device is crucial for accurate medication delivery and monitoring.

When the equipment is damaged, it may lead to inconsistent infusion rates or mechanical failures. This poses serious risks, particularly for vulnerable patients who rely on precise dosages of life-saving medications.

Moreover, a malfunctioning device can create delays in treatment. Medical staff might need to divert their attention to troubleshooting instead of focusing on patient needs.

The visual impact of a crack also raises concerns about hygiene and safety protocols in healthcare settings. A visibly damaged device can foster distrust among patients regarding the quality of care they receive.

In critical situations, any lapse in performance could have dire consequences, reinforcing the importance of ensuring that all medical equipment remains in optimal condition at all times.

Conclusion: Investing in proper maintenance

Proper maintenance of medical equipment like the Alaris 8100 L is not just about keeping devices functional; it’s about ensuring patient safety and care quality. Investing in regular checks and repairs can significantly reduce the likelihood of issues such as cracks, which could jeopardize both equipment performance and patient outcomes.

Repairing a cracked Alaris 8100 L or preventing such damage requires attention to detail. Employing routine inspections, using protective cases, and educating staff on proper handling techniques are all effective strategies that contribute to longevity. The financial implications of neglecting maintenance can be substantial when considering repair costs, potential replacements, and most importantly, the impact on patients.

A picture of a cracked Alaris 8100 L serves as a stark reminder of what’s at stake. It underscores the need for vigilance in maintaining these essential tools within healthcare settings. Prioritizing upkeep translates into better service delivery and enhanced trust between healthcare providers and patients alike.

Investing time and resources into maintenance pays off by ensuring that medical devices operate safely—and effectively—when they are needed most.

Stay updated with the United States National Cricket Team here.